Automated Test Equipment

The Automated Test Equipment (ATE) can be designed primarily using Commercial Off-The-Shelf (COTS) test instrumentation. This type of design makes it easy to swap out instruments, for example, when sending an instrument out for calibration.

The ATE design may be "generic", i.e., one ATE can be used for multiple applications. In this scenario, the ATE is designed with a super-set of instrumentation required to test multiple products. A Custom Interface Adapter or Custom Test Harness is designed to provide the connection from the ATE to each unique Unit-Under-Test (UUT).

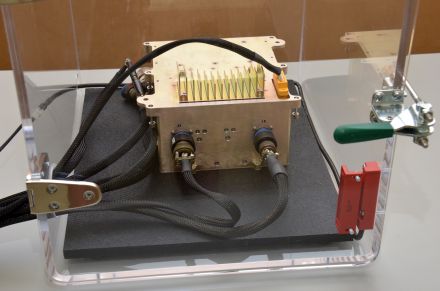

Test Hardware

- The Automated Test Equipment (ATE) is computer-controlled allowing for a fully automated test with minimal operator intervention.

- The ATE is comprised of test instrumentation which is modular, off-the-shelf industry standard devices.

- Communication protocols may be emulated with the ATE hardware (CAN Bus, ARINC-429, Serial, etc.).

- An Interface Panel on the ATE will allow Custom Interface Adapters or Custom Test Harnesses to access the ATE resources necessary to test individual assemblies.

Test Software

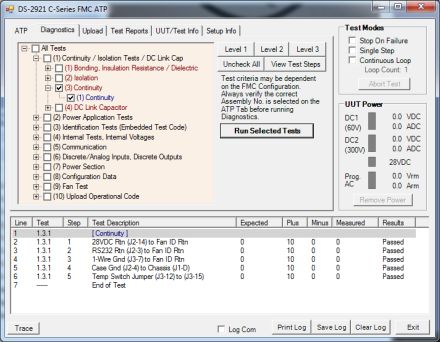

- The Test Software is a custom program designed to automate the test process.

- When operator involvement is required (e.g., connecting the UUT) the Test Software will provide detailed prompts.

- The Test Software is written to be fully compliant with the manufacturer's Test Requirement Specifications.

- If troubleshooting, the Test Software will provide the options of single-stepping tests, looping tests, and stopping on failures to help identify and troubleshoot problems.

- All test stimulus and response is displayed on-screen during the test, and in a Test Report following the test.

- All test data is stored in a database for retrieval and analysis.

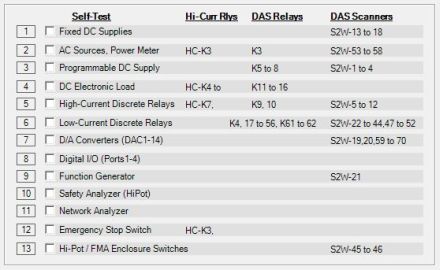

Self-Test

Self-Test capability is provided with each ATE, which includes a Self-Test Adapter and Software. All instrumentation and ATE resources are tested using loop-back methods.

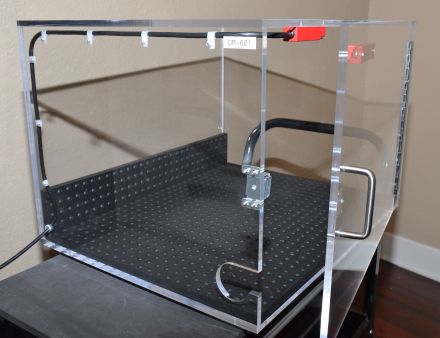

Safety Enclosures

In some cases the product being tested may require additional safety precautions. For example, if the product contains moving parts, uses high voltages, or generates unsafe noise levels.

designwave can provide the appropriate safety enclosure for the products being tested.

Functional Testing

Functional testing will individually stimulate each electronic circuit in the Unit-Under-Test (UUT), and then measure the UUT response to the applied stimulus. This method insures the proper operation of each circuit, and identifies individual circuit failures.

This test method is used to verify the UUT circuitry as it would function during normal operation. Tests are performed on electronic assemblies and products using the Input/Output (I/O) connections built into the product.

Functional testing assures proper operation after assembly, stress-screening tests, and before shipment. It is also used to determine if electronics are defective when returned from the field.